Flexible corporate event hall

Located a 10-minute walk east of the St. George campus is the U of T Engineering Partnerships Office, a new co-location centre for U of T Engineering’s partners. This centre features a flexible, 4,090 square-foot event hall, perfect for hosting large meetings, seminars, receptions and other events attended by up to 250 people.

Advanced research facilities & equipment

As a world-leader in engineering research and education, U of T Engineering is equipped with incredible facilities, specialized research equipment and diverse engineering expertise. Many of these facilities are open to external partners outside of U of T, such as companies and other academic institutions. Each facility has its own guidelines around use, access and pricing.

Looking for a particular type of research equipment within U of T?

This new database provides a current listing of research equipment available for shared use to both U of T and external researcher partners.

Biomanufacturing & mass spectrometry

Housed within the Department of Chemical Engineering & Applied Chemistry at U of T Engineering, BioZone unites researchers from several disciplines who share a passion for innovation in environmental and industrial biotechnology. With expertise in bioinformatics, genomics, enzymology, microbiology, process engineering, mathematical modelling and more, BioZone features both a Mass Spectrometry Facility and a Biomanufacturing Facility.

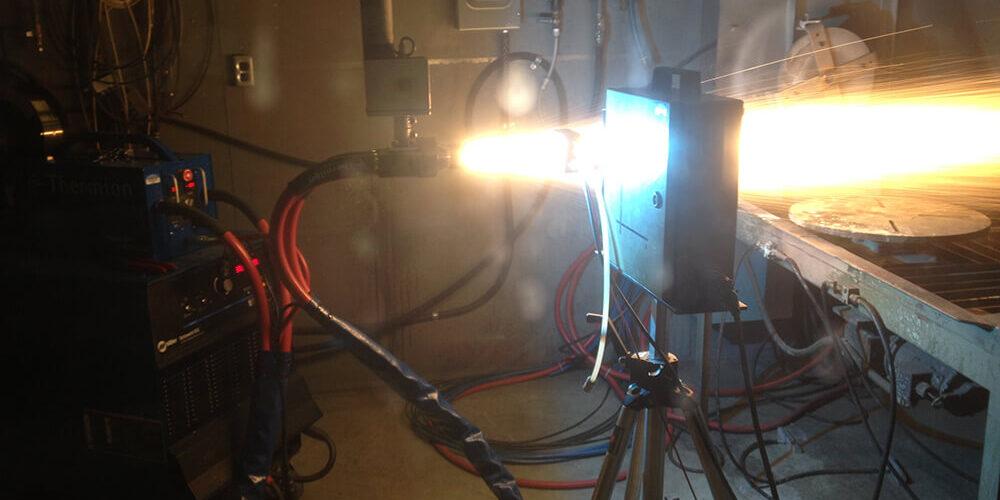

Advanced coating technologies

A part of the Department of Mechanical & Industrial Engineering, the Centre for Advanced Coating Technologies (CACT) offers a wide range of equipment and facilities to cover virtually all areas of thermal spray coatings, right from deposition of the coating to its testing and characterization. CACT is a research leader in fields related to surface tension phenomena, droplet impact, and liquid spray and atomization. The centre also offers a unique combination of strong computing facilities to perform various 2D and 3D computer simulations based on complex numerical models.

Microfluidic device fabrication & prototyping

The Centre for Research and Applications in Fluidic Technologies (CRAFT) consists of and supports a community of experts from diverse sectors collaborating on R&D projects to develop leading-edge microfluidic devices. Research facilities housed at U of T include the Device Foundry for rapid prototyping and small-scale device fabrication, and the Tissue Foundry for preclinical validation of devices. Capabilities include photo- and soft-lithography, 3D printing, laser cutting, injection molding, microscopy, imaging and more.

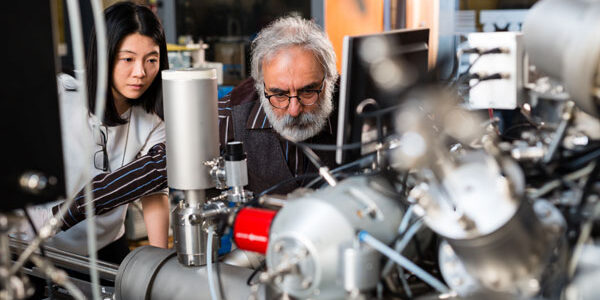

Analysis of advanced materials

Open Centre for the Characterization of Advanced Materials (OCCAM) provides researchers with access to state-of-the-art surface analytical equipment and electron microscopic expertise. With competitive rates and superior quality, OCCAM actively caters to both academic and industrial needs. This unique facility provides both analytical services and direct (self-operation) access to instrumentation for trained/authorized users. Capabilities include electron spectroscopy, scanning probe microscopy, electron microscopy and more.

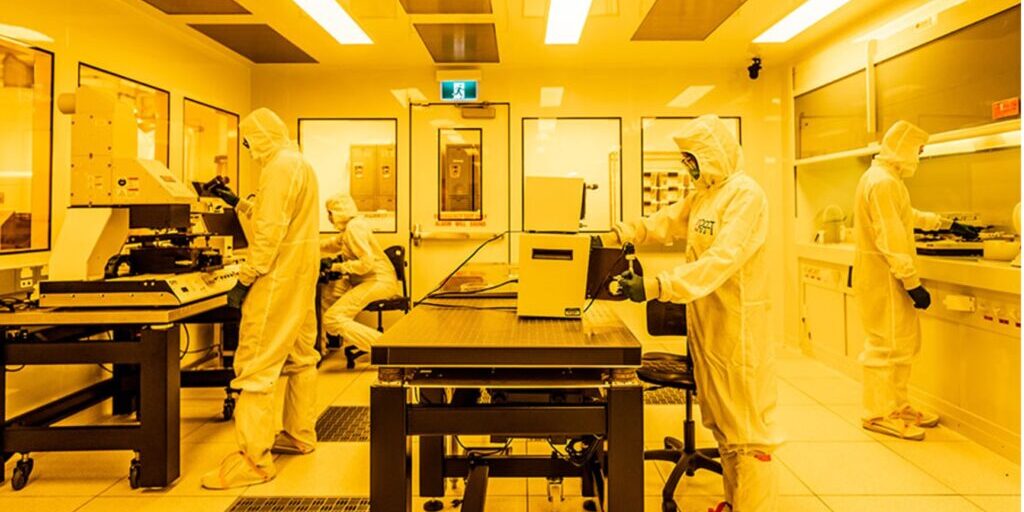

Nanofabrication & prototyping

The Toronto Nanofabrication Centre (TNFC) is an interdisciplinary research and service centre that provides access to state-of-the-art nanofabrication facilities, collaborative research networks, advanced educational opportunities and information exchange events for registered users and clients. Capabilities include electron beam lithography, photolithography, deposition, etching, dicing and packaging and imaging and characterization. TNFC facilities are open to both academic and industrial researchers, making it an ideal choice for open-access prototype development and testing.

Air quality analysis

Southern Ontario Centre for Atmospheric Aerosol Research (SOCAAR) is an interdisciplinary centre for the study of air quality, with a focus on how pollutants impact human health and the environment. It brings together medical personnel, atmospheric chemists and environmental engineers, and promotes collaborative research through access to state-of-the-art facilities and partnerships with government and industry. Research capabilities include a field measurement facility, aerosol chemistry facility, cell culture and biochemistry facility, concentrated ambient particle exposure facility, engine combustion and emissions facility, a rooftop measurement site and a monitoring station on Toronto Island.

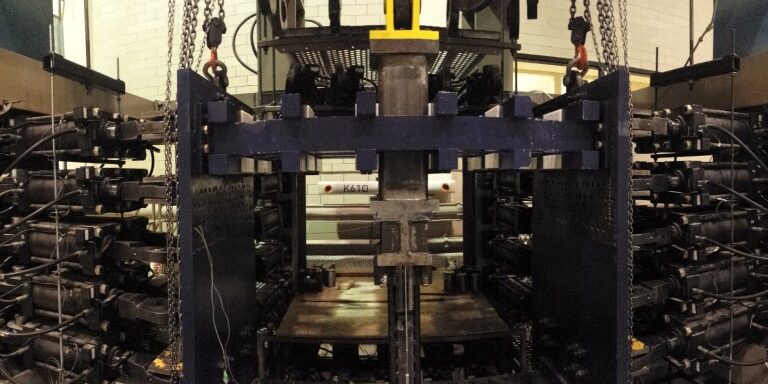

Testing large-scale structures

Housed within the Department of Civil & Mineral Engineering, the Structural Testing Facilities is among the top few of its kind in North America. The main laboratory spans two buildings and includes a concrete-mixing lab, machine shop, welding bay and woodworking area. Equipment available in this space include static and dynamic actuators, DOF shaking tables, shell element tester, shear panel tester, blast generator, column testing frame and many more machines for all your structural testing needs.

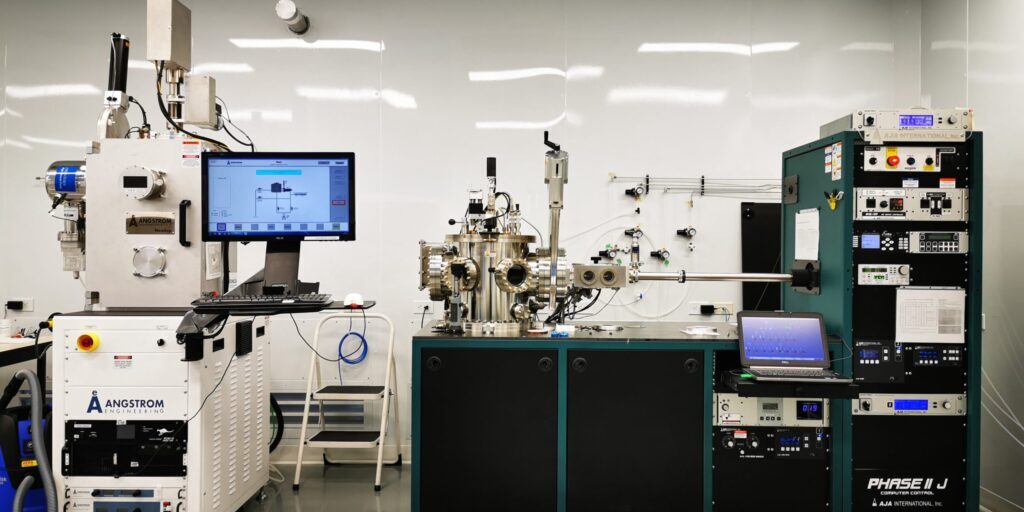

Advanced characterization & processing

Housed within the Department of Materials Science & Engineering, the Walter Curlook Materials Characterization & Processing Laboratory serves the advanced characterization needs of U of T faculty and students as well as external researchers in academia and industry. The laboratory houses X-ray diffractometers, equipment for inductively coupled plasma optical emission spectrometry, laser particle size analyzer, sample preparation equipment and more.

Facilities open to partners within U of T

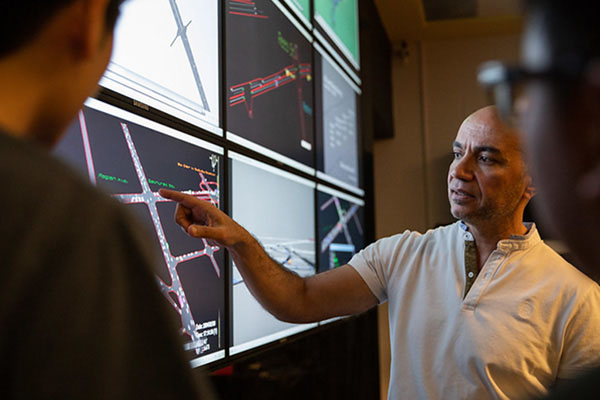

Immersive viewing experience for groups

The Stewart L. Blusson Visualization Facility is a state-of-the-art space featuring a large, high-resolution display wall and surround-sound system that provides an immersive viewing experience for 25-30 people. Measuring 10 x 40 feet, it is the first narrow pixel pitch, direct view, LED-based solution deployed for research at any university in Canada. Whether you use the screen for data display or analysis, or for a presentation, demonstration or workshop, this space is ideal for hosting an unforgettable experience with larger-than-life imagery.

Machine shop for faculty, staff and students

The machine shop housed within the Department of Mechanical & Industrial Engineering (MIE Machine Shop) features machining equipment and provides technical services for U of T Engineering students and faculty. All users must pass a basic machining course and meet other requirements. Shop technicians also provide professional services to support faculty and student research at the University of Toronto, including design consultation, precision machining, fitting and assembly of prototypes and custom-designed parts.